What are levelling feet?

Levelling feet (also called levelling mounts, machine feet, or adjustable feet) are components commonly attached to the base of machinery, furniture, equipment, racks, and other items, allowing the height and level to be adjusted so that the item sits stably on uneven surfaces.

Fixed feet often only provide height adjustment via a threaded stem without angular correction; adjustable/tilting feet, on the other hand, allow for angular alignment on sloping or uneven ground.

Rencol produces both fixed feet and adjustable feet, heavy-duty and lightweight, in various materials, including thermoplastic, die cast zinc and stainless steel.

What are the components of a levelling foot?

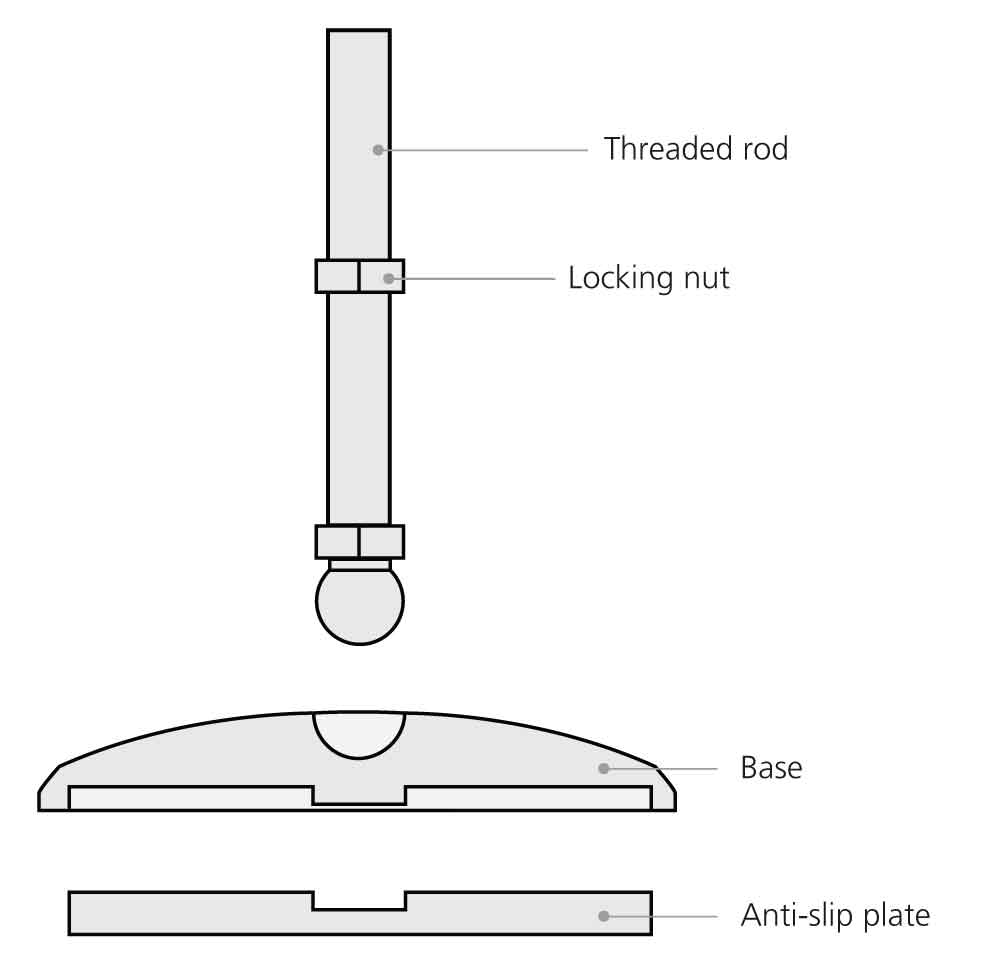

| Component | Function |

|---|---|

| Base | A base sits directly on the floor. Levelling feet bases either have bolt-holes (which allow the base to be bolted to the floor) or rest on the surface. Rencol offers bases manufactured from thermoplastic, glass-reinforced nylon, die-cast zinc, and stainless steel. A swivel or tilting base can be used to compensate for uneven ground. |

| Threaded rod | A threaded rod provides height adjustment to ensure the equipment is level. The thread size, length, and material should be chosen for strength, corrosion resistance. |

| Locking nut | A nut is used to lock the height once set. |

| Anti-slip plate (optional) | An anti-slip plate provides improved grip and vibration dampening. |

What criteria do you need to consider when selecting a levelling foot?

When choosing levelling feet, consider the following:

- Load capacity

- Determine the total static load the equipment will carry. Divide the total by the number of feet to get the per-foot load.

- Include dynamic loads if the equipment vibrates or moves.

- Include a safety margin in your calculation.

- Base size

- Larger base diameter spreads load better and gives more stability.

- Larger bases also help reduce pressure on the floor and reduce the risk of damage or sinking.

- Thread size & length

- The thread must match the mounting hole or fixings on the machine/furniture.

- The length must allow sufficient adjustment range (height differences) without bottoming out or being too long (which may weaken the installation).

- Adjustment range & level-ability

- For heavily uneven surfaces, a swivel base or tilting foot is advantageous.

- If there are only slight height differences, a rigid adjustable-height foot may suffice.

- Floor attachment (bolt-down vs freestanding)

- Bolt-down bases allow the foot to be fixed to the floor, making them useful for machines that must not move or slide under load or vibration.

- Non-bolt-down bases rely solely on friction or weight and might need rubber bases or pads to prevent slipping.

- Environmental considerations

- Where corrosion is possible (salt, humidity), stainless steel or coated metals should be used.

- When chemicals or cleaning agents are present, it is recommended to use compatible materials, such as nylon and stainless steel.

- In hygiene-sensitive environments (food, medical, and pharma environments), smooth, cleanable surfaces are often required.

- Ease of adjustment & maintenance

- Hex base or flats for spanner adjustment help, especially when space is tight.

- Lock nuts or jam nuts to prevent creep.

- Cost vs performance trade-offs

- Heavier-duty or specialised materials cost more.

- Picking more than needed lowers risk but increases cost and weight.

How to install levelling feet

- Prepare the mounting surface & base

- Ensure the machine or furniture base is rigid and can accommodate the feet in the desired positions.

- Clean the floor and base of debris, oil, or dust.

- Select positions for feet

- Generally, one foot near each corner or load-bearing point. For heavy machines, sometimes additional middle supports will be required.

- Ensure the feet are placed so that the load is well distributed and there is no excessive overhang that might cause tipping.

- Fit the feet

- Install threaded rods into the base. Use appropriate nuts, washers, etc.

- If bolt-down pad, align and mark bolt holes, drill fasteners and secure.

- Initial height adjustment / balancing

- Make rough adjustments so the base of the equipment is close to level using a spirit level or laser.

- Adjust each foot until it just makes contact with the floor .

- Fine levelling

- Use precision level in two directions (e.g. front-to-back, side-to-side). Adjust feet iteratively until level.

- If the feet have swivel bases, adjust them to conform to the floor plane as needed.

- Locking the adjustment

- Tighten any lock nuts or jam nuts against the body.

- If bolt-down, secure the base to the floor after levelling is completed.

- Check for tilt/stress points

- Ensure the load does not induce unwanted torque or bending in the stem or base.

- The equipment frame should sit square – no torsion.

- Final inspection under load

- Load the equipment to its expected working load and re-check level-ness and stability; sometimes load causes deflection.

- Adjust again if necessary.

Levelling feet maintenance

To ensure longevity and reliability:

- Periodically re-check the level, especially if equipment is moved or the floor shifts.

- Inspect for corrosion, wear, or loosening of threads, lock nuts.

- Lubricate threads if needed (for metal-metal) to prevent seizing.

- Clean the base and anti-slip plate to prevent the accumulation of dirt or debris, thereby reducing contact.

- Replace feet if the base or thread is damaged, bent, cracked or exceeding safe wear.

Engineering calculations to consider

If you want a more precise design approach, here are some calculation/engineering points:

- Static load per foot = (Total weight of equipment + contents + ancillary items) ÷ Number of feet

- Allow for dynamic load factor: If the machine vibrates, or loads shift (e.g. conveyor belts, moving parts), add a dynamic load factor (e.g. 1.2-1.5×).

- Stress & safety factor: Design thread/stem & base for stresses well below yield; include safety factors (often 2-3× load).

- Floor pressure: Base area × load per foot gives pressure on the floor; ensure the floor & pad can handle this pressure without damage.

- Thread shear & buckling: Very long and unsupported threaded rods may buckle; ensure the stem length-to-diameter ratio is safe; use thick or reinforced rods for tall adjustments.

Rencol’s levelling feet

-

Model 01 LF

Free-standing Nylon Adjustable Levelling Foot

View variations -

Model 05 LF

Mini Adjustable Levelling Foot with Hex

View variations -

Model 04 LF

Mini Adjustable Levelling Foot

View variations -

Model 01 ASP

TPE Rubber Anti Slip Plate for Levelling Feet

View variations -

Model 03BD LF

Bolt-down Stainless Steel Levelling Foot

View variations -

Model 03 LF

Free-standing Stainless Steel Levelling Foot

View variations -

Model 02BD LF

Bolt-down Die Cast Zinc Levelling Foot

View variations -

Model 02 LF

Heavy Duty Levelling Foot

View variations -

Model 01BD LF

Bolt-down Nylon Adjustable Levelling Foot

View variations