Introduction to Cam Locks

Cam locks are precision-engineered fastening devices which are widely used in various industrial and commercial applications. Their robust construction and efficient locking mechanisms make them ideal for securing enclosures, cabinets, and machinery access points.

This technical guide provides an overview of the available cam locks and how design engineers, buyers, and product specifiers can select the appropriate one for their specific application.

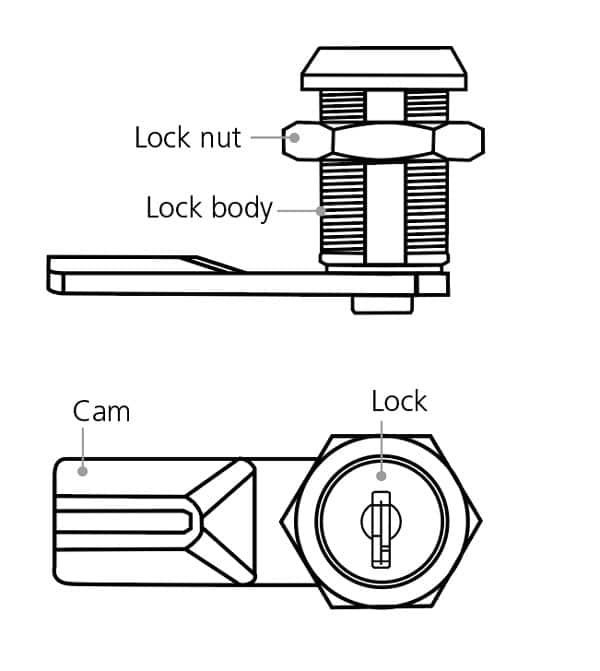

1. Cam lock components

- Lock body: The core component, typically a threaded cylindrical housing containing the locking mechanism.

- Lock nut: The lock nut rotates around the lock body to secure the cam lock in a panel or door.

- Cam: A flat or offset metal plate attached to the lock cylinder’s rear.

- Lock and key or wing knob: A lock and key provides security. Several types of keys and locks are available. Where security is not a priority, a simple wing knob is an ergonomic shape to twist the cam and open a door.

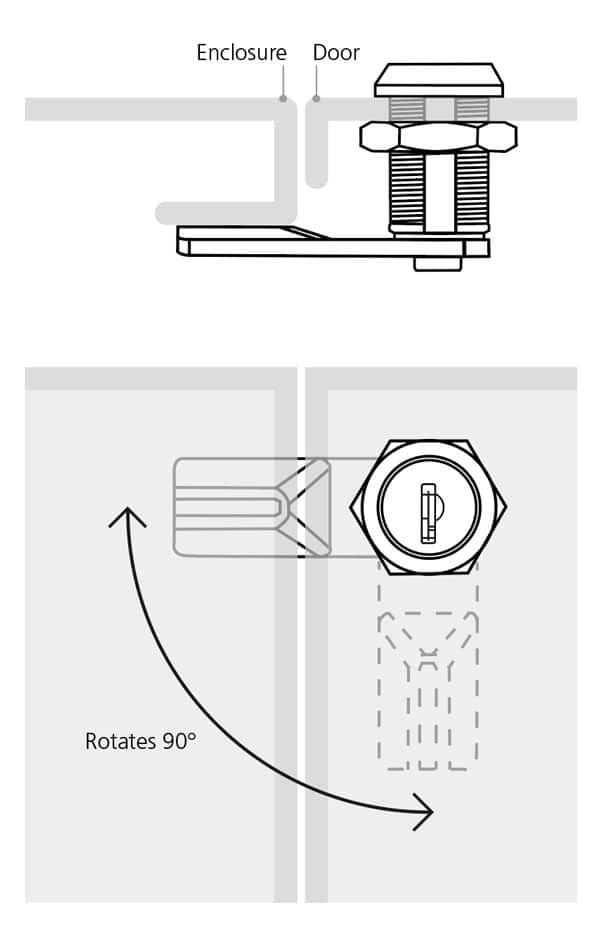

2. How to operate a cam lock

This 90-degree turn engages or disengages the lock by interfacing with a strike or latch point on the adjacent surface.

To unlock, rotate the key or knob by 90 degrees in the opposite direction.

3. Cam lock technical specifications

When selecting a cam lock, design engineers must consider the cam lock material, finish, dimensions, locking mechanism, security requirements, and environmental rating.

Cam lock materials:

- The lock body is commonly fabricated from die-cast zinc alloys. This material offers a good balance between strength and corrosion resistance.

- The cam is typically manufactured from zinc-plated steel or stainless steel. The appropriate cam material should be selected to withstand the operational stresses and moisture in the application environment.

Cam lock finish:

- Surface treatments such as zinc plating, chrome plating and black powder coating enhance durability and provide aesthetic uniformity.

Cam lock dimensions:

Cam lock dimensions:

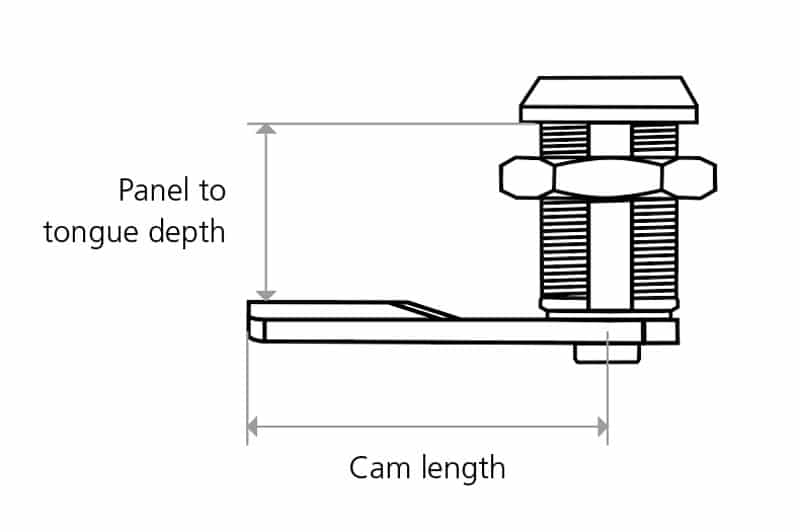

- The cylinder length determines the panel-to-tongue depth. This measurement varies to accommodate different panel thicknesses.

- Cam length and offset are tailored to the panel width and specific locking requirements, as well as mounting configurations.

Lock type:

Lock type:

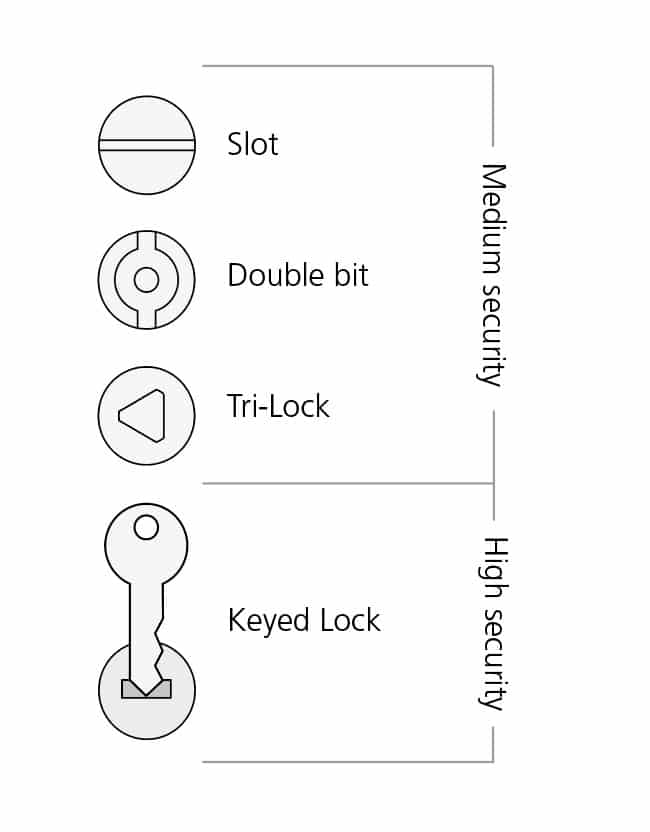

- There are various types of lock and key combinations available.

- A traditional flat key and lock are the ideal solution for high-security applications.

- For medium security applications – and particularily where many locks may be installed in one area – a slot key (for use with a flathead screw driver), or a double-bit or tri-lock key and lock combination is preferred.

Environmental ratings:

- Ingress Protection (IP) ratings, such as IP54, indicate resistance to dust and water ingress, essential for outdoor or industrial applications.

4. Cam lock industries & applications

Cam locks are used in a wide range of applications across various industries, including commercial, residential, automotive, aerospace, and medical.

Typical applications include: enclosures, electrical cabinets, electrical panels, vending machines, display cases, post boxes, office furniture, lockers, and numerous types of cabinets in vehicles, trains and aeroplanes.

4. How to install a cam lock

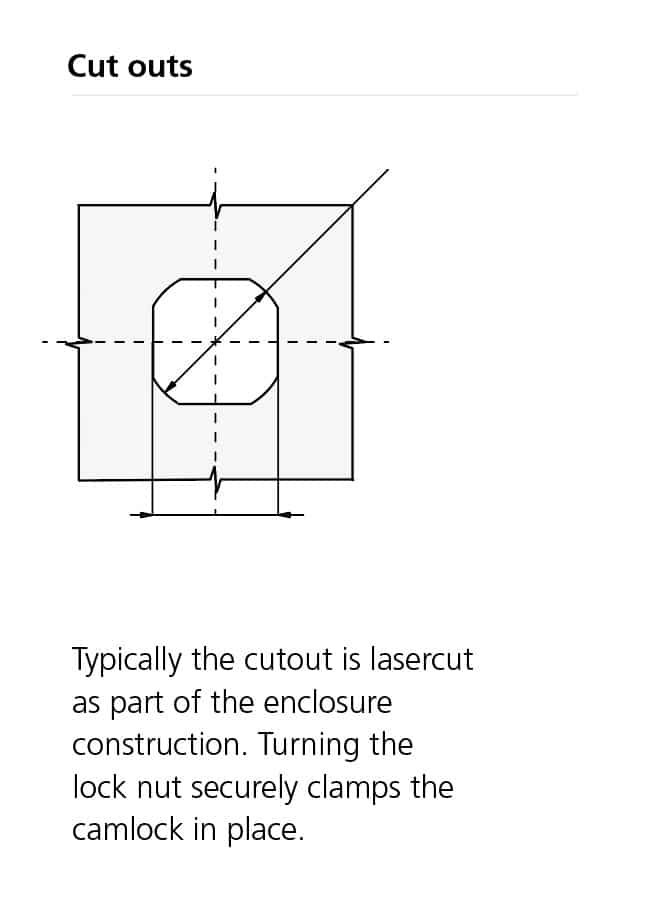

- Panel preparation: Ensure the mounting hole diameter matches the lock cylinder specifications. If the panel is steel, the hole should be cut before painting or powder coating.

- Cam alignment: Align the cam appropriately to engage with the strike or latch mechanism upon rotation. Most cam locks can be configured for left-hand and right-hand opening.

5. How to maintain cam locks

To maintain functionality and extend service life:

- Lubrication: Regularly apply a suitable lubricant to the moving parts to reduce wear and prevent corrosion.

- Inspection: Regularly inspect for signs of wear, corrosion, or damage, and replace components as necessary.

- Environmental protection: For outdoor applications, consider additional protective measures such as seals or covers to enhance resistance to environmental factors.

6. Rencol’s cam locks

-

Model 15 ML

Chrome Plated Camlock with Cylinder Lock & Key

View variationsNEW -

Model 20 ML

Cylinder Cam Lock, Quarter Turn Latch for Padlocks

View variationsNEW -

Model 21 ML

Push-to-Close Cylinder Lock, Slam Lock, Chrome Plated Diecast Zinc

View variationsNEW -

Model 19 ML

Quarter-Turn Cam Lock with Nylon Plastic Housing

View variationsNEW -

Model 18 ML

Quarter-Turn Cam Lock with Wing Knob, Silver

View variationsNEW -

Model 17 ML

Die-Cast Zinc Quarter Turn Camlock with Key

View variationsNEW -

Model 16 ML

Stainless Steel Quarter Turn Camlock with Square Key

View variationsNEW -

Model 14 ML

Quarter Turn Camlock Latch with Cylinder Lock & Key

View variationsNEW -

Model 12 ML

Quarter-Turn Cam Lock with Wing Knob

View variationsNEW -

Model 11 ML

Cylinder Cam Lock, Quarter Turn Latch for Padlocks

View variationsNEW -

Model 10 ML

Quarter Turn Camlock Latch with Cylinder Lock & Key

View variations -

Model 09 ML

Zinc plated or Stainless Steel Quarter Turn Camlock Latch

View variationsNEW -

Model 08 ML

Quarter Turn Camlock Latch with Square or Slot Key

View variations -

Model 07 ML

Diecast Zinc Cam Latch Cylinder Lock with Hex/Allen Key

View variations

Cam lock dimensions:

Cam lock dimensions: Lock type:

Lock type: