A quick guide to detent pins

Rencol manufactures a comprehensive range of detent pins in numerous sizes. The ideal detent pin will vary from application to application and will depend on various factors. Here's a quick guide to begin with:

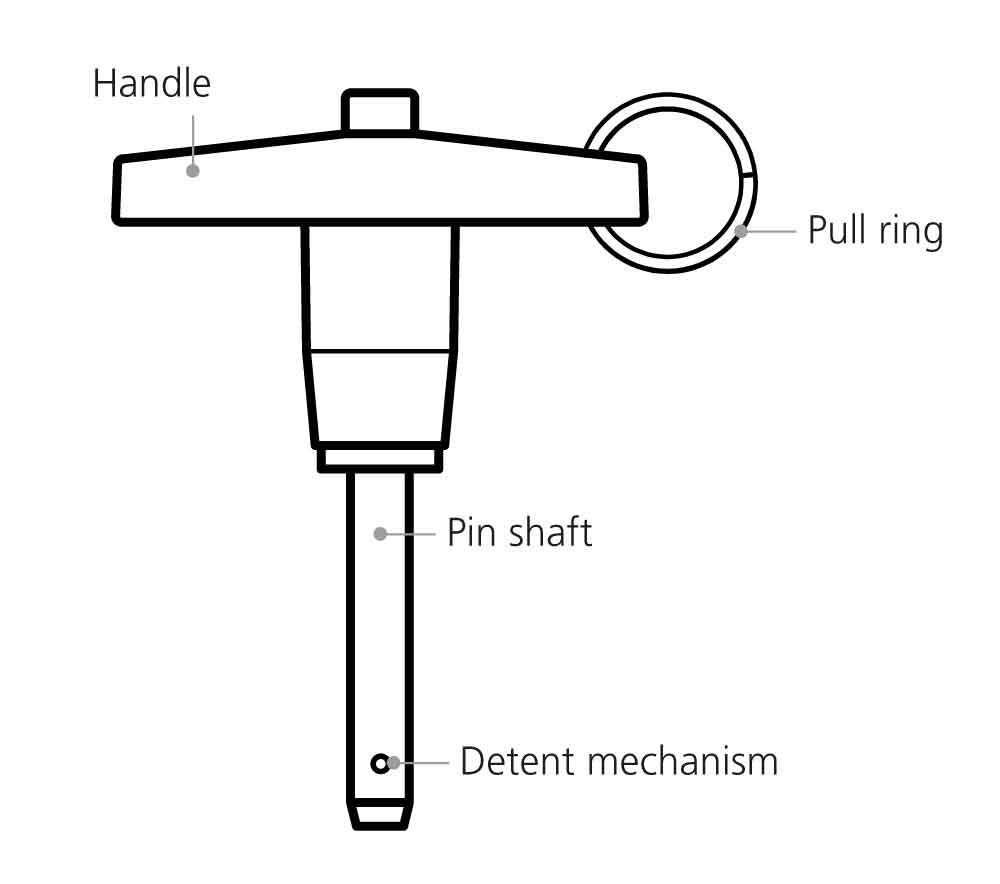

Detent pin construction and components:

Handle, head or grip:

The head of a detent pin provides a handling area for insertion and removal. Rencol stocks detent pins with either a plain shaft and pull ring, T-handle, or button-head style.

Pull-ring:

All of our detent pins include a ring where a lanyard can be attached to secure the detent pin while not in use.

Pin shaft:

Usually cylindrical and machined from stainless steel, carbon steel, or aluminium. The size of detent pin shafts varies depending on specific application requirements, such as strength, length, and load rating. Rencol stocks detent pins with diameters ranging from 5mm to 16mm and lengths from 16mm to 94mm.

Detent mechanism:

Small stainless steel balls protrude from the pin’s surface under spring pressure. They retract when pushed into a mating hole and snap back out to secure the pin.

Detent pin material:

While some manufacturers offer detent pins in carbon steel, aluminium and stainless steel, we have found that stainless steel delivers optimal performance. Where a detent pin has a handle or grip, this can be manufactured from aluminium without reducing reliability or strength.

Sizing and selection criteria:

What should be considered when choosing a detent pin?

Pin diameter: Must match the mating hole’s diameter with proper clearance.

Usable length: Measured from the underside of the head to the point where the locking mechanism engages.

Shear strength: Determined by material, diameter, and load requirements.

Operating environment: Consider corrosion, vibration, and temperature.

Ergonomics: The handle style should be suitable for both frequency and ease of operation. The inclusion of a button will make it easier to retract the detent pin.

Examples of applications of detent pins:

Aerospace: Commonly used for quick assembly and disassembly of panels and components.

Automotive: Securing hitch receivers, seat components, and removable panels.

Marine: Retaining rigging components.

Industrial machinery: Positioning fixtures, jigs, and tooling.

Consumer products: Adjustable sports equipment and various types of folding mechanisms.

How to install a detent pin:

1. Align the pin with the mating hole.

2. Push the pin through; detent balls retract during insertion.

3. Once fully seated, the detent balls snap outward, securing the pin.

4. To remove, apply axial force (pull) or depress a push-button (if applicable).