Technical guide to spring plungers

Spring plungers (also known as ball plungers) are precision components used to apply controlled force to position, index, or secure mechanical parts. Their compact design, reliability, and versatility make them essential in mechanical assemblies, jigs, fixtures, and a wide range of industrial applications. Rencol manufactures a wide range of spring plungers in standard threaded sizes from M3 to M20, and in push-fit diameters from 2mm to 12mm.

What is a spring plunger?

A spring plunger is a device consisting of a threaded or smooth body that houses a spring-loaded ball or pin. The spring applies axial pressure, forcing the ball or pin outward. This allows the plunger to provide consistent pressure, positioning, or indexing force when engaging with a surface, groove, or detent.

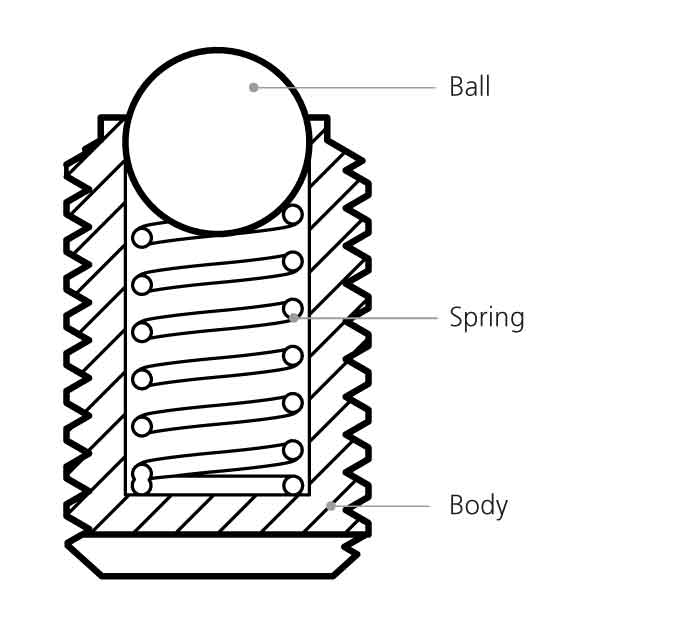

Components of a spring plunger

Components of a spring plunger

Ball

The spherical shape can rotate in any direction and applies a constant force away from the plunger body.

Spring

Within the spring plunger body is a spring which applies a force on the ball.

Body

The spring plunger body is usually manufactured from either stainless steel, blackened steel, or thermoplastic, most commonly acetal.

What are the key features of a spring plunger?

Spring-loaded mechanism: Provides repeatable and consistent force.

Self-retaining: Designed to remain seated in mounting holes or threads.

Compact design: Allows integration into tight or confined spaces.

How do spring plungers work?

When the ball is pressed, the spring inside the body compresses. Upon release, the spring pushes the ball outward, providing a controlled and repeatable force. This simple mechanism allows spring plungers to act as indexing, positioning, or pressure elements in assemblies.

Where are spring plungers used?

Indexing & positioning: Used in detents, locating fixtures, and adjustable mechanisms.

Securing components: Preventing loosening or movement in assemblies.

Tooling & fixtures: Holding workpieces in jigs and fixtures.

Electronics & connectors: Providing pressure contact in circuit boards or connectors.

Automotive & aerospace: Used in latches, adjustable mechanisms, and access panels.

How to install a spring plunger

Select proper type: Choose based on load requirements, material compatibility, and application environment.

Prepare mounting hole: Drill and tap to the appropriate size if using threaded plungers.

Install the spring plunger: Use a flathead screwdriver or press fit, depending on design.

Test Function: Ensure the ball/pin moves smoothly under pressure and returns correctly.

Components of a spring plunger

Components of a spring plunger