Ray Engineering was incorporated through an amalgamation of two small companies operating from the same premises in Frogmore Street, Bristol.

The two companies produced the Joylight Engine, described as “the outcome of 15 year’s experience in the construction and design of Internal Combustion Engines”. It was designed specifically for electric lighting in the home.

Our first foray into producing small plastic parts. Bakelite knobs and switches were produced for electrical equipment.

Moved to Waterdale Works on Southmead Road. The company design, developed and manufactured switchboards, and would continue to do so until the 1960’s.

Along with 12 local engineering firms, Ray Engineering Co. founded Bristol Engineering Manufacturers Association (BEMA).

Engineers from Ray Engineering spoke on subjects such as metal spraying, plastic moulding, and the maintenance of electric pumps.

During the WW2 many employees were exempt from National Service so the company could provide manufacturing services to the MOD. A special “Ray” badge was issued to spare the stigma of not signing up!

The MOD already had a plastics supplier called Ray, so they were unable to use this name. They decided instead to adopt an abbreviation of the whole company name. As required, the company rebranded their products “RENCOL” and we have traded as such ever since.

Rencol begins to focus more on plastic knobs, handles and hand wheels. The company is soon trusted by many leading manufacturers of machinery and equipment.

Factory overhauled with modern thermoset injection moulding machines and early development of multi-cavity tooling. For many decades one of our early compression machines was housed in The Industrial Museum.

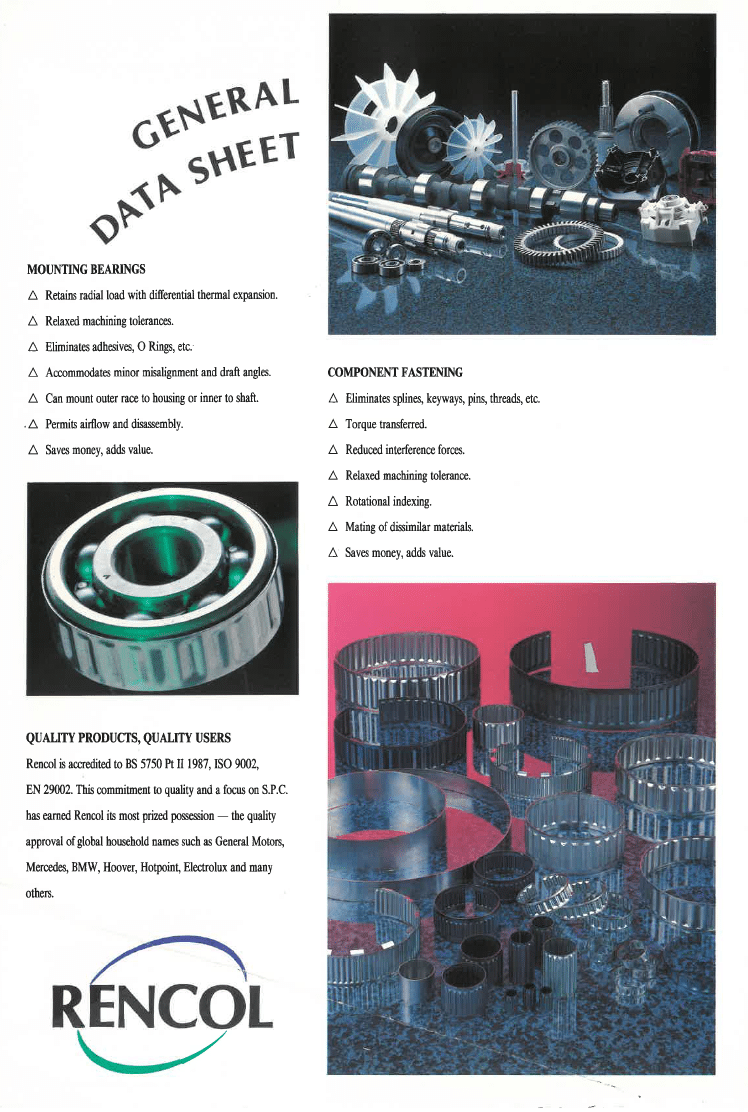

Rencol designs, develops and manufactures tolerance rings. A unique product which is used to join cylindrical mating components.

Tolerance rings were adopted by many well known brands, including General Motors, Mercedes and BMW. The company went on to become very successful in its own right, eventually being sold to Saint-Gobain.

The company was an early adopter of an ERP computer system which was linked to all moulding machines and used for scheduling and monitoring.

Expansion of product range and manufacturing processes and materials, including a move from Duroplast to nylon and polypropylene.

Bought by US group, manufacturing expanded to multiple worldwide facilities including local engineering and logistics offices.

Thanks to the greatly expanded manufacturing capabilities the breadth and depth of our product range grew exponentially. In particular, metal manufacturing increases substantially to include CNC machining, forging, pressing and die casting.

Many new UK and international distributors begin selling Rencol products, greatly increasing the company’s reach both at home and abroad.

Rencol’s diverse manufacturing capabilities allow us to produce a wide range of metal parts with greater complexity and functionality. A comprehensive range of enclosure hardware is developed, including locks, latches, handle and specialist hinges.